CONVENTIONAL GRINDING WHEELS

Resinoid grinding wheels

Need a versatile solution for cutting and finishing complex materials?

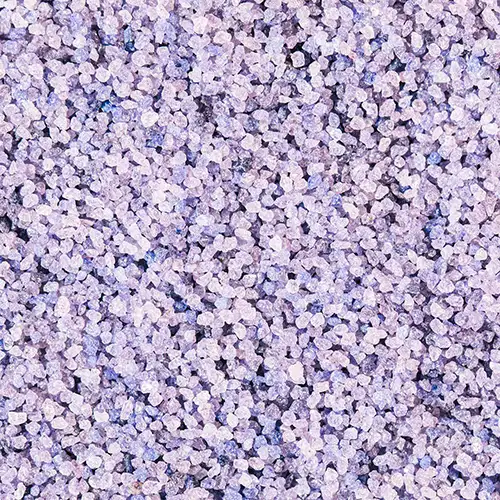

Made with a resinoid bond and premium quality abrasives, resinoid grinding wheels deliver optimum profile durability combined with an excellent surface finish.

Vitrified grinding wheels for cutting and finishing

Ermoli resinoid grinding wheels are ideal for cutting, deburring and finishing a vast range of materials. Perfectly designed for surface grinding with lapping machines or cup grinding wheels, external/cylindrical grinding, internal grinding, centreless grinding, deburring (bench grinding), and sharpening.

Delivery time for grinding wheels is 45 days.

Available dimensions for different grinding applications

Resinoid grinding wheels are designed to effectively damp vibrations while machining thereby ensuring uniform contact with the surface. This means a more even and finer quality finish.

With their combination of premium quality abrasives and resinoid bond, these grinding wheels ensure an impeccable finish, removing flaws and minimising any surface defects, even with complex and hard-to-machine materials.

The resinoid bond gives grinding wheels an extraordinary form holding capacity during prolonged use, ensuring dimensional consistency and longer lasting profiles, even for heavy-duty machining.

Resinoid grinding wheels are particularly well-suited when dry machining without the use of any coolants. Their structure allows optimal heat dispersion, preventing any distortions and maintaining the integrity of the workpiece.

Ermoli resinoid grinding wheels are also the preferred solution of spring manufacturers for all their cutting and grinding needs.

Special requirements?

If you need special sizes or a customised design, our team of experts is on hand to develop personalised solutions that answer all your specific needs.

Our material library

Our corundum, silicon carbide, CBN and diamond grinding wheels are created with unique formulas specially developed by our engineers to meet all your stock removal requirements.

Sectors utilising resinoid grinding wheels