CONVENTIONAL GRINDING WHEELS

Vitrified grinding wheels

Need a solution for high-precision grinding and particularly hard materials?

Made with a vitrified ceramic bond and a range of abrasives, vitrified grinding wheels are the ideal solution for precision grinding ferrous materials, such as steel and cast iron, and non-ferrous materials like carbon, ceramic, fibreglass, plastic, leather, paper, and cereals.

Vitrified wheels for grinding and sharpening

Ermoli vitrified grinding wheels are ideal when precision grinding and finishing during the following operations: surface grinding (tangential grinding with lapping machines or cup grinding wheels), external or cylindrical grinding, internal grinding, centreless grinding, bench grinding/deburring and sharpening.

Delivery time for grinding wheels is 60 days. Delivery time for abrasive segments is 45 days.

Available dimensions for different grinding applications

The vitrified bond gives grinding wheels considerable mechanical strength and hardness. Ideal for machining ferrous and non-ferrous materials which demand high stock removal and lower working temperatures.

Thanks to their properties, they hold their form during prolonged periods of machining, ensuring consistent precision over time.

The porous structure offers optimal dissipation of heat, which reduces the risk of the workpiece overheating and prevents any distortion or damage to the material.

Rapid removal of large quantities of material, while maintaining a high degree of precision for rough grinding as well as finishing.

Special requirements?

Please contact our consultants if you need special sizes or a customised design.

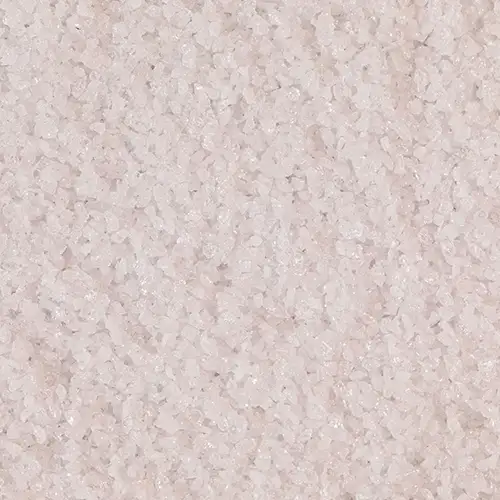

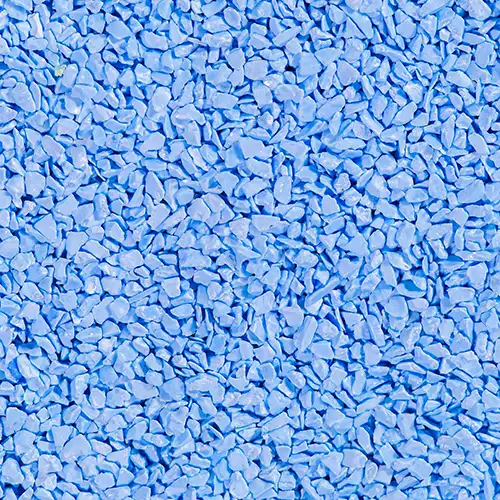

Our material library

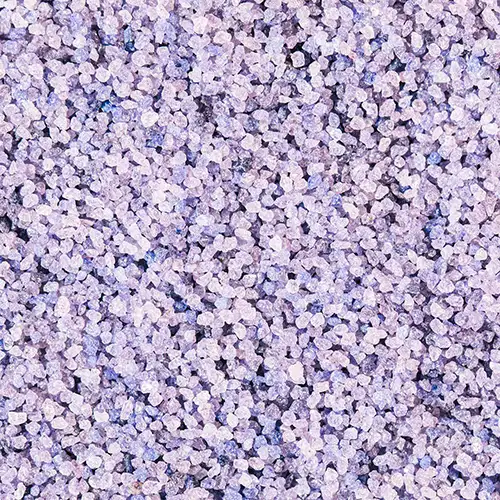

Our corundum, silicon carbide, CBN and diamond grinding wheels are created with unique formulas specially developed by our engineers to meet all your stock removal requirements.

Sectors utilising vitrified grinding wheels